For workshops and manufacturers that wish to control their budgets while also needing flexible purchasing methods, purchasing Chinese laser welding machines has become a practical option. As more and more Chinese laser welding equipment manufacturers enter the international market, buyers now have access to products covering different power levels, different configurations, and different price ranges, making it easier for them to find the appropriate equipment according to their own application needs.

However, a lower quoted price does not always mean lower overall cost. This article outlines practical considerations to help buyers make smarter, more cost-effective decisions when purchasing Chinese laser welding machines.

What to Consider Before Buying Chinese Laser Welding Machines

Before contacting Chinese laser welding machine suppliers or or starting to compare prices, enterprises must first clearly define their actual production requirements. Otherwise, their subsequent choices may easily go astray.

Key points to clarify include:

- Welding materials: Carbon steel, stainless steel, and aluminum impose different power and stability requirements.

- Typical thickness range: Most workshops operate within a limited thickness window and do not need extreme power capacity.

- Duty cycle and working pattern: Continuous production and intermittent welding place very different demands on equipment.

- Usage scenario: Handheld welding, integrated stations, or future automation readiness should be evaluated realistically.

If these factors are not properly addressed at the beginning, buyers are likely to choose overly high specifications. As a result, both the procurement and operation costs increase, but the production efficiency does not actually improve.

Key Factors That Affect the Cost of Chinese Laser Welding Machines

Understanding the components of costs can help buyers make a more objective comparison of laser welding equipment from China.

Main cost factors include:

- Power configuration vs real usable output

High peak power figures look attractive but rarely improve daily production if unused.

- Cooling system design

Water-cooled systems add infrastructure, maintenance, and failure points.Air-cooled laser welding machines often reduce long-term operating cost for many workshops.

- Core component quality

Laser source stability, optical system design, and control logic matter more than appearance or rarely used features.

- System integration level

Poor integration increases setup time, adjustment effort, and operator dependence.

By paying attention to these factors, buyers can avoid spending their money on things that do not actually bring value.

Choosing Reliable Chinese Laser Welding Machine Manufacturers and Suppliers

The choice of suppliers can significantly affect the subsequent usage costs. When evaluating Chinese manufacturers and suppliers of laser welding machines, buyers can focus on the following aspects:

- Manufacturer vs trader

Direct manufacturers usually offer clearer configurations and stronger technical support.

- Engineering and integration capability

Suppliers with in-house R&D are better positioned to deliver stable, workshop-ready systems.

- After-sales response and documentation

Slow support and unclear manuals quickly increase downtime-related costs.

- Spare parts availability

Non-standard or difficult-to-source parts extend repair cycles and reduce production efficiency.

Choosing the right supplier often leads to greater cost savings than simply lowering prices. Moreover, this advantage becomes more and more pronounced over time.

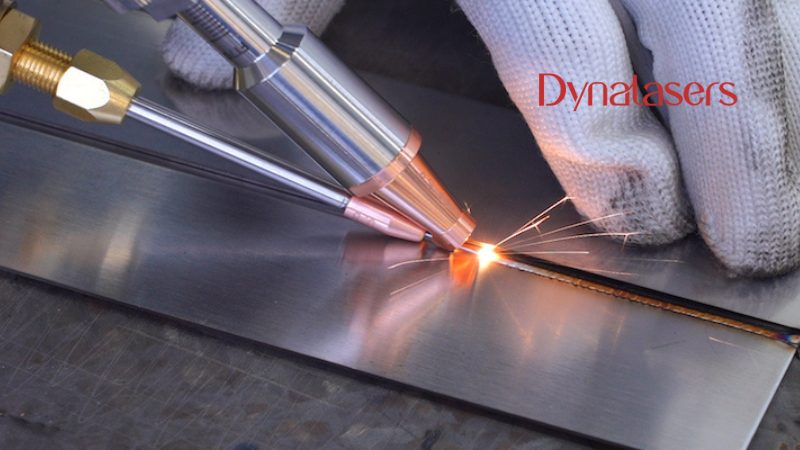

Why Dynalasers Is a Cost-Effective Chinese Laser Welding Machine Manufacturer

Among the laser welding machine manufacturers in China, Dynalasers laser welding machines place greater emphasis on designs that are in line with actual workshop usage and cost control over the long term, rather than relying on exaggerated parameters for marketing. Its main features and advantages include:

Self-Developed Fiber Laser Source

- Laser source and welding gun are independently developed by Dynalasers

- Optimized for high-reflective materials such as aluminum and stainless steel

- Energy absorption optimized, reflectivity-related instability reduced

- Handheld welding gun weight: ≈ 0.48 kg, significantly reducing operator fatigue

Integrated System Design

- Laser source, handheld welding gun, wire feeding unit, and gas supply integrated into one compact system

- Reduces external connections and setup complexity

- Shortens installation and commissioning time

- Improves overall ease of operation and stability

Multiple Configuration Options

- S Series: ultra-lightweight design, total machine weight < 8 kg, easy to carry and deploy

- M Series & D Series: output power up to 1800 W, suitable for thicker materials and higher-duty applications

- Supports multiple operating modes, including welding, cleaning, and cutting, within a single system.

Air-Cooling Technology

- Air-cooled system, no external chiller required

- Stable operation within ambient temperature range of -15°C to 40°C

- Eliminates water-cooling maintenance, leakage risks, and auxiliary power consumption

- Lower system complexity and improved long-term reliability

Fast and Efficient Weld Formation

- One-step welding process with rapid weld pool formation

- Stable output enables consistent penetration and weld appearance

- Even less-experienced operators can achieve acceptable weld quality quickly

- Reduces rework caused by parameter fluctuation

Continuous Operation Capability

- Designed for continuous operation up to 7 days without interruption under normal conditions

- Suitable for small-batch and medium-duty industrial production

- Maintains output stability during extended working cycles

Warranty and After-Sales Support

- 2-year standard warranty

- Professional technical training provided

- Dedicated after-sales service to support long-term use

- Helps reduce downtime and long-term ownership risk

In actual production, the key lies in whether it is easy to use and can be used stably. For buyers, choosing Dynalasers is often more convenient and makes it easier to establish long-term cooperation.

Common Mistakes When Buying Cheap Chinese Laser Welding Machines

Many buyers who are in search of low-cost Chinese laser welding equipment often focus solely on the price during the inquiry stage, while neglecting the issues that may arise during actual use.

Common mistakes include:

- Underestimating training time: Complex interfaces and unstable parameters delay productive use.

- Ignoring long-term stability: Frequent adjustments lead to inconsistent quality and rework.

- Overlooking maintenance complexity: Poor documentation and non-standard components increase downtime.

- Assuming all suppliers provide similar support: Limited after-sales capability quickly turns into hidden cost.

To avoid these problems, the key is to put the equipment into a real production environment for observation, rather than merely comparing parameters and calculating costs on paper.

Practical Strategies to Buy a Chinese Laser Welding Machine

If one wants to purchase Chinese laser welding equipment at a lower cost, the buyer needs to adopt a more practical and executable purchasing strategy.

Effective approaches include:

- Compare configurations instead of prices: Ensure power, cooling, and components match actual usage.

- Evaluate operating simplicity:Machines that are easier to use reduce training and idle time.

- Ask about long-term support and maintenance: Clear service processes reduce unexpected downtime.

- Focus on cost-effective design, not “cheap” pricing: Stability and reliability often save more money over time.

The reduction in costs stems from rational decisions rather than blindly pursuing the lowest bid.

Frequently Asked Questions

1. Is it really cheaper to buy Chinese laser welding machines?

Yes, but the prerequisite is that the equipment should match the actual production requirements. The real cost advantage comes from stability and the long-term usage cost, rather than the lowest quotation.

2. How to find reliable Chinese laser welding machine manufacturers?

Good manufacturers will clearly explain the configuration and usage. In case of any problems, they can provide timely support. Dynalasers has a better understanding of the actual conditions in the workshop, the selection process is straightforward and using their products is also more worry-free.

3. Are cheap Chinese laser welding machines suitable for long-term use?

Cheap machines are suitable for occasional use, but not for long-term operation. What really matters is stability, usability and good maintenance, rather than the lowest price.

4. How do I choose the right power for a Chinese laser welding machine?

The appropriate power level depends on the type of material being welded, its thickness, and the duration of continuous operation, rather than the maximum power indicated by the manufacturer. Many factories have found that choosing an appropriate and sufficient power level can actually save more money.

5. Why does total cost of ownership matter more than purchase price?

The money saved initially is likely to be offset by the subsequent operating and downtime costs. The real savings come from stable and easy-to-maintain equipment.

Conclusion

Buying Chinese laser welding machines at a lower cost is not about chasing the lowest price, but about choosing equipment that truly fits your production needs and delivers stable, long-term performance.

If you have specific application requirements, please contact Dynalasers laser welding company today. By communicating with them about your materials and working conditions, you will be able to obtain a customized configuration solution that is more suitable for your workshop.